Why bother?

Tuesday, December 27th, 2011Many of the things that go trundling through my brain while working start with a thread on FPN. Lots of fodder there…. The specific post that started me down the multiple rabbit trails was about a cap that wouldn’t screw onto a pen. It’s repairable, but the owner didn’t especially want to hear the answer that I gave, and thought about buying another cap. That would work too, but there’s no guarantee that another cap would fit his barrel. I’ll put that on my list for another post.

But that thread reminded me of something that I’ve had on my mind for some time now. I’ve been experimenting with replating the trim on pens. David Isaacson and I have had discussions about how it turns out, Daniel Kirchheimer has a whole page of arguments for and against. I grant you , it will wear eventually, but it can’t be worse than the plating on a modern Parker Sonnet. David Nishimura has opined that you’d be better off buying a replacement cap.

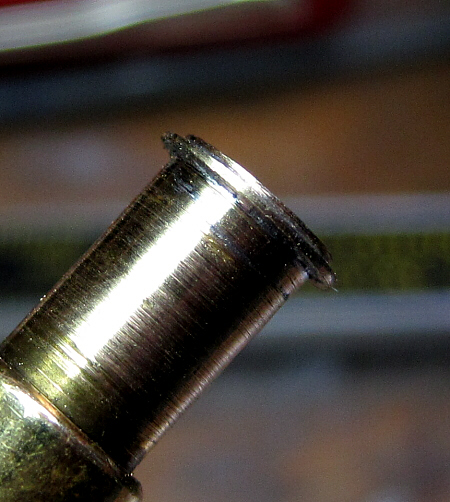

Thoughts along the same line come up with celluloid crack repair, or the previously mentioned Parker Vacumatic cap that doesn’t screw onto the barrel. It’s one of the pens where the cap fits on other pens, but the this cap and barrel won’t work together. The cap jumps threads, or simply doesn’t engage with the barrel because the threads on both halves are worn. The damage can be repaired, but it isn’t necessarily cheap. “Just buy another cap,” they say. Grand. Simple solution. Except that the supply of “other caps” is in fact finite. The same for pens that have clean, unbrassed trim. The same for Parker Vacumatic pumps that are intact, nibs that are crack free and all that.

For years now we’ve had the luxury of throwing NOS parts at damaged pens when we have them, or harvesting parts from other pens to repair the one on the bench, rather than finding appropriate intervention to repair the damage to the pen on the bench. Instead of repairing or replacing the sac nipple on that 51 aerometric filler or Duofold section we just replace them. I think that pen repair guys often get to be a bit too casual when repairing pens if they have a large stash of parts because it’s easier to replace than fix. But we won’t get away with that forever.

At some point we will run out of NOS parts and donor pens, and we’ll rue the day that we so casually tossed a damaged part and reached for the replacement. Then what will we do with the “family pens” that really can’t be fixed and must have replacement parts to write again?

I would argue that there are (or should be) two primary rules of pen repair, not just one. First is “do no harm.” The second should be “replace only when it’s impossible to repair.” Obviously this requires a higher level set of skills, but to me that’s what professional pen repair is all about. Anyone can learn to replace a sac, but only some develop the skills needed to truly repair a pen.